3D LiDAR Scanning

Laser Scanning provides the ability to capture the existing conditions to a high degree of accuracy, and review the data multiple times for various uses.

In July 2001, Northway/Photomap/Remote Sensing Ltd. purchased North America’s first ILRIS 3D laser scanner, and became the first service agency offering laser scanner services with a dynamic range in a single scan of 3m to 1500m, and point to point accuracy of 10mm.

Since this time, we have purchased 3 more scanners. The NextEngine desktop 3D scanner, the Optix and our newest addition to the family is a FARO Photon Scanner. With our full compliment of scanners we can meet any scanning requirements you have.

We have completed numerous projects for a wide variety application including those listed below.

- Busy Highway Engineering Application

- Topographic Surveying

- Topographic Mapping Updates

- Mining Surveying

- Landfill Site Measurements & Volumes

- Manufacturing Retrofits

- Cultural and Historic Surveys

- Detailed Surveying At Airports

- Construction Inspection

- Safety & Production Sensitivity Surveys

- Quantity Surveys

- Golf Course Surveys

- Petrochemical Surveys

- Industrial Sites

- Ships for Retrofit

- Power Plants

- Facility Inspection

- Accident and Forensic

- Archaeology Site Surveys

- Animation base Data (Wire Frame)

What does each scanner do?

Ilris-3D (Intelligent Laser Ranging and Imaging System) collects and defines the immediate area around the setup location of the scanner. Once setup by the operator, the scanner emits 2000 laser pulses per second which locates all features in a 40 degree x 40 degree field of view to an accuracy of 10mm. Two highly calibrated mirrors inside the unit direct each laser pulse such that the direction of the pulse is known. The scanner records the time lapse from pulse emission to the receipt of the return signal, calculates the distance based on the time of flight, joins the distance with the angles of the mirrors and a position in space is known for the returned laser pulse. In addition to the position, all objects reflect the laser light at different levels such that this returned level of laser light is mapped into a gray scale image for viewing purposes by the client. For areas that are larger than the scanner’s field of view, multiple scans are completed and joined during post processing such that a complete area can be converted from reality to virtual reality.

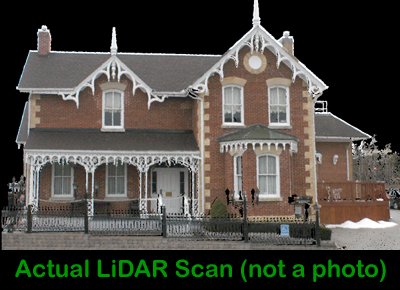

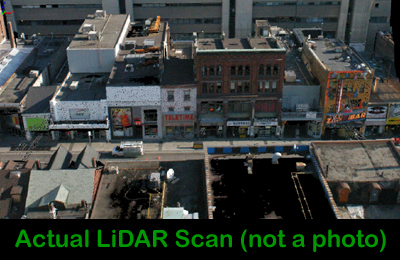

In 2004, Northway/Photomap/Remote Sensing Ltd. added to ILRIS-3D the ability to transfer colour from high resolution digital images to each data point collected, such that the scanned 3D images now appear in colour. Each of the scanned data points is assigned an RGB value such that the images appear in colour, and retain the ability to be viewed, measured, or inspected from any angle desired by the client.

The NextEngine scanner is used for small object scanning. The field size in the macro mode is 13 cm x 9.6 cm and in the wide mode it’s 34 cm x 25.5 cm. The dimensional accuracy for the macro mode is approximately 0.012 cm and in the wide mode approximately 0.038 cm. The acquisition speed of the scanner is 50,000 processed points per second and in a typical small model are about quarter-million points, after oversampling and optimization. The NextEngine uses a MultiStripe Laser Triangulation (MLT) technology with twin arrays of four, Class 1M solid state lasers with custom optics. It also takes the RGB colour texture capture for precision-locked geometry correlation. The scans can be imported to SolidWorks or can also be output into a STL, VRML and other formats for exchange with other systems.

The Optix 400L scanner is used for small to medium size objects. The depth of field is in a range of 30 cm to 90 cm. At 30 cm the resolution is approximately 0.017 cm and at 90 cm it’s approximately 0.05 cm. The point density is up to 1000 x 1000 and the field of view is 30 degrees. This scanner can scan an area of about 1.5 square feet in a range between 30 cm and 90 cm.

The Optix 400L scanner is used for small to medium size objects. The depth of field is in a range of 30 cm to 90 cm. At 30 cm the resolution is approximately 0.017 cm and at 90 cm it’s approximately 0.05 cm. The point density is up to 1000 x 1000 and the field of view is 30 degrees. This scanner can scan an area of about 1.5 square feet in a range between 30 cm and 90 cm.

The FARO Photon Scanner is used for medium to large size objects or areas. This is a phase shift scanner with a range of up to 75 meters. The measurement speed is 120,000 points per second with a 3 mm accuracy. The vertical field of view is 320 degrees and 360 degrees for horizontal field of view. The color kit enables us to capture parallax free colored laser scans.

What do I get as a final Product?

Upon completion of the project, all raw data files are provided to the client, with a viewer of the data so they can review the data themselves. Depending upon the project requirements, AutoCAD, Microstation, or other format deliveries are available for the point clouds, or the data can be converted into a vector file for various applications. Our LiDAR specialists would be pleased to discuss your requirements in detail.

We are Equipped for your project

Having been the first in LiDAR service work with an ILRIS-3d scanner, we have developed a series of applications for our system to suit your needs. Safety is the foremost requirement for all projects involving your staff and ours, that is one reason we selected the ILRIS-3D scanner. ILRIS-3D is completely eyesafe in all modes of operation, even when its invisible beam is viewed directly through binoculars. We can capture information regarding unsafe conditions from safe locations using the large dynamic range of 3m up to 1000m, and a small generator, which we provide, provides the power requirements.

Northway/Photomap/Remote Sensing Ltd. has also developed many methods of capturing the data required. From an elevated position in the rear of a pickup truck, an elevated position inside a building, a rolling truck on a rail line, or the standard surveyors tripod in the required locations.

Northway/Photomap/Remote Sensing Ltd. has been producing ILRIS-3D laser Scans for the past six years, our experience will provide you with insight and your project data in the shortest possible time. Contact us at your convenience to discuss your requirements, or to request a demonstration disk for viewing of sample data. If you are interested in a demo or would like more information please contact Steve Dixon.